简介

随着科技的发展,自动化程度也越来越高,人们可以从重复性的工作岗位转向更有意义的职业。

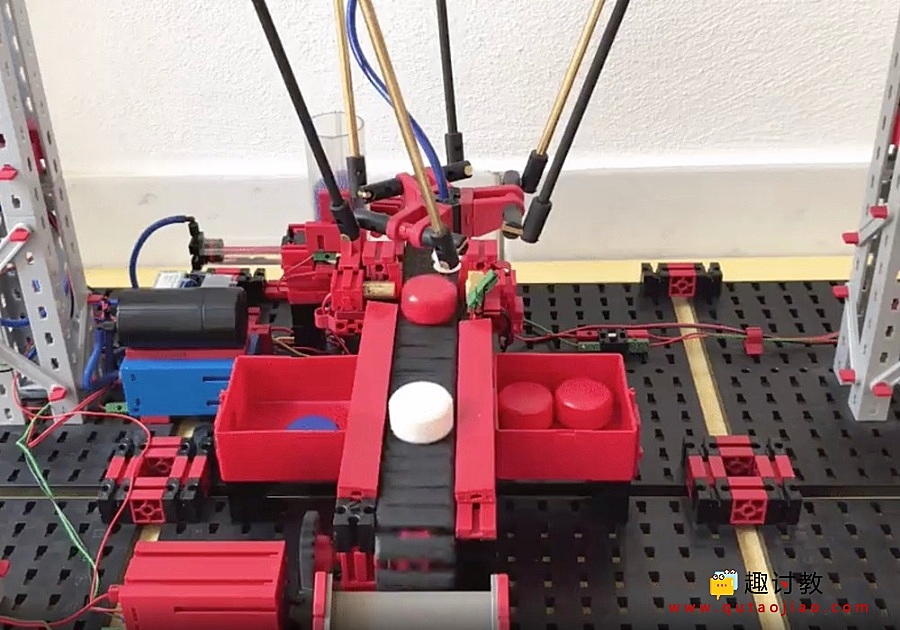

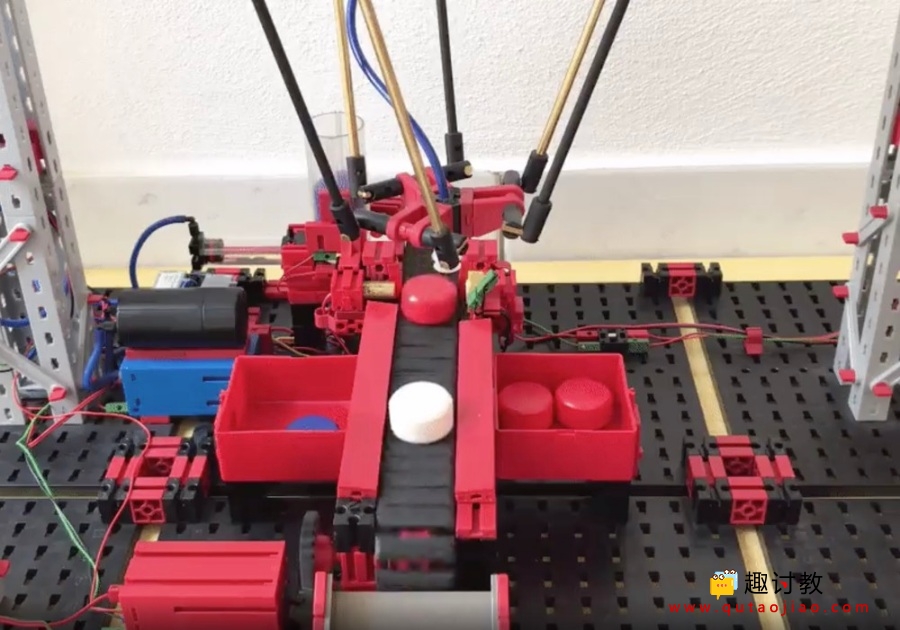

制造工业机器人并不一定意味着在昂贵的硬件上花费大量资金。这款分拣机器人就是由Arduino Mega控制而成,是一款相当简单的机器。尽管如此,它并不缺乏速度或精度来完成它的工作:机器人从传送带上拾取物品,并按照颜色对它们进行分类,类似于工业拾取和放置机器人。

步骤一 材料准备

硬件准备:

Arduino Mega 2560

步进电机

通用3D打印机

软件准备:

Arduino IDE

Arduino web 编辑器

Arduino microsoft visual studio代码扩展

步骤二 原理说明

与3D打印机中经常使用的简单运动学(例如线性运动学)不同,这款机器人的运动过程更复杂且不易理解。为了控制具有笛卡尔坐标的三角洲机器人,需要所谓的反向运动学。根据Robert L. Williams II发表的一篇论文,已经实现了三角机器人的逆运动学。 尽管这似乎是计算上的昂贵,但三角运动学比其他机器人运动学有一些很好的优势。首先,它们非常快速和精确,其次具有相当好的操作范围。

运动跟踪位置由激光光栅捕获。这使机器人知道物品何时通过传送带上的某个位置。此外,通过读取编码器信号来测量传送带速度。这让机器人知道物品移动的速度。鉴于该信息,可以计算机器人的运动,以便在正确的时间选择物品。

真空夹具物品由真空夹具操纵。由于我没有真空泵,我已经找到了另一种解决方案:

有两个气缸彼此相邻安装。第一个气缸连接到一个阀门,要么压入或压出。第二个圆筒连接到真空杯。当压力施加到第一气缸时,它延伸。由于两个活塞彼此机械连接,第一气缸的运动也迫使第二气缸延伸,该运动在第二气缸内产生真空。该真空用于拾取物品。

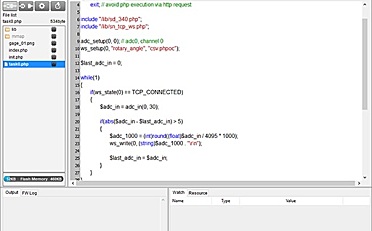

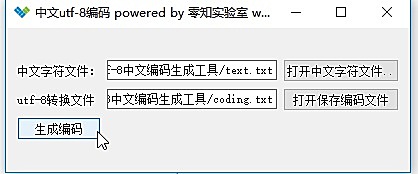

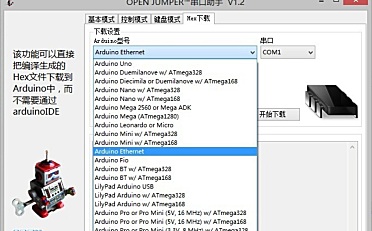

步骤三 编写程序

#include

#include

#include

#define LOW_SPEED 50

#define MEDIUM_SPEED 80

#define MAX_SPEED 100

/* Vacuum gripper 1_1

June 2019

- pressure control

- adaptive conveyor speed

July 2019

- stack

- color filter

*/

DeltaRobotKinematics delta;

StepperMotor & mot1 = *shield.getStepper(2); // pre-configured stepper

StepperMotor & mot2 = *shield.getStepper(1);

StepperMotor mot3; // half-bridge based stepper motor

DCMotor coil31;

DCMotor coil32;

DCMotor conveyor;

DCMotor gripper;

DCMotor compressor;

DCMotor laser;

DCMotor separator;

long posM1 = 0;

long posM2 = 0;

long posM3 = 0;

volatile int posConveyor = 0;

volatile int pressure;

const uint8_t limitSwitch1 = I5;

const uint8_t limitSwitch2 = I6;

const uint8_t limitSwitch3 = I8;

const uint8_t conveyorEncoder = C3;

const uint8_t photocell = C4;

const uint8_t stack = D4;

const uint8_t MPX_pin = I3;

const uint8_t colorSensor = I4;

const int whiteLowerThreshold = 100;

const int whiteUpperThreshold = 175;

const int redLowerThreshold = 196;

const int redUpperThreshold = 270;

const int blueLowerThreshold = 480;

const int blueUpperThreshold = 510;

bool pass = false;

long passTime = 0;

uint8_t currentSpeedProfile = LOW_SPEED;

void pressureControl()

{

pressure = analogRead(MPX_pin);

if (compressor.getSpeed() < 1)

{

if (pressure < 140)

{

compressor.on();

}

}

else

{

if (pressure > 187)

{

compressor.off();

}

}

}

int rad2StepM1(double radian)

{

return (int) ((radian + 0.785) * 95.51);

}

int rad2StepM2(double radian)

{

return (int) ((radian + 0.785) * 127.35);

}

int rad2StepM3(double radian)

{

return (int) ((radian + 0.785) * 127.35);

}

void posP2P(double x, double y, double z)

{

delta.inverseKinematics(x, y, z);

bool t = false;

while (!t)

{

t = mot1.stepping(posM1, rad2StepM1(delta.getPhi2()));

t &= mot2.stepping(posM2, rad2StepM2(delta.getPhi3()));

t &= mot3.stepping(posM3, rad2StepM3(delta.getPhi1()));

}

}

void posCP(double x1, double y1, double z1, double x2, double y2, double z2)

{

posP2P(x1, y1, z1);

double vect[] = {x2 - x1, y2 - y1, z2 - z1};

double vectLength = sqrt(pow(vect[0], 2) + pow(vect[1], 2) + pow(vect[2], 2));

double unitVect[3];

for (int i = 0; i < 3; i++)

{

unitVect[i] = vect[i] / vectLength / 2.0; // unitVect: Length 0.5mm

}

vect[0] = x1;

vect[1] = y1;

vect[2] = z1;

int iterations = vectLength * 2; // equivalent to vectLength / 0.5

for (int i = 0; i < iterations; i++)

{

vect[0] += unitVect[0];

vect[1] += unitVect[1];

vect[2] += unitVect[2];

posP2P(vect[0], vect[1], vect[2]);

}

posP2P(x2, y2, z2);

}

void speedProfile(int profile)

{

mot1.velocity(profile);

mot2.velocity(profile);

mot3.velocity(profile);

}

int colorDetection()

{

int n = 4; // #of measurements

long measurements[n];

for (int i = 0; i < n; i++)

{

measurements[i] = analogRead(colorSensor);

delay(30);

}

// calc average

long avg = 0;

for (int i = 0; i < n; i++)

{

avg += measurements[i];

}

avg /= n;

// calc error

long error = 0;

for (int i = 0; i < n; i++)

{

error += (avg-measurements[i])*(avg-measurements[i]);

}

Serial.print("Error: ");

error /= n;

Serial.println(error);

if (error < 3)

{

// measurement accurate, return average

Serial.println(avg);

return avg;

}

else

{

// measurement inaccurate, return 1023

return 1023;

}

}

void referencing()

{

delay(50);

bool ref = false;

while (!ref)

{

ref = mot1.referencing(posM1);

ref &= mot2.referencing(posM2);

ref &= mot3.referencing(posM3);

}

delay(50);

}

// ISR

void conveyorISR()

{

posConveyor++;

}

void setup() {

Serial.begin(115200);

Serial.println("Delta Robot @ MegaDueShield");

delta.setUpperLegsLength(75);

delta.setLowerLegsLength(180);

delta.setBaseSize(41.83);

delta.setPlatformSize(26);

coil31 = *shield.getDCMotor(5);

coil32 = *shield.getDCMotor(6);

conveyor = *shield.getDCMotor(1);

gripper = *shield.getDCMotor(7);

compressor = *shield.getDCMotor(8);

laser = *shield.getDCMotor(2);

separator = *shield.getDCMotor(4);

mot3.setHalfBridge(coil31, coil32);

mot1.motorConfig(200, 80, 600, 400);

mot2.motorConfig(200, 120, 800, 400);

mot3.motorConfig(200, 60, 800, 400);

mot1.attachLimitSwitch(limitSwitch1);

mot2.attachLimitSwitch(limitSwitch2);

mot3.attachLimitSwitch(limitSwitch3);

pinMode(photocell, INPUT_PULLUP);

pinMode(stack, INPUT_PULLUP);

pinMode(conveyorEncoder, INPUT_PULLUP);

attachInterrupt(digitalPinToInterrupt(conveyorEncoder), conveyorISR, CHANGE);

shield.rgb(0, 0, 150);

delay(200);

shield.rgbOff();

referencing();

delay(500);

speedProfile(80);

laser.on();

Timer1.initialize(300000);

Timer1.attachInterrupt(pressureControl);

}

void loop() {

mot1.release();

mot2.release();

mot3.release();

while (!digitalRead(stack))

{

// no item in stock

if (!pass)

{

conveyor.off();

}

else

{

if ((millis() - passTime) > 2000)

{

// conveyor on until white item has passed

pass = false;

}

}

delay(300);

}

pass = false;

conveyor.cw(135);

delay(400);

int colorVal = 1023;

while (colorVal > 1000)

{

colorVal= colorDetection();

}

// separate

separator.on();

delay(80);

separator.off();

if (colorVal < whiteUpperThreshold)

{

// color is white

delay(300);

pass = true;

passTime = millis();

}

else

{

// color is either red or blue, remove item from conveyor

delay(20); // wait to prevent light barrier from triggering falsely

while (!digitalRead(photocell))

{

}

posConveyor = 0;

long t0 = millis();

while (posConveyor < 140)

{}

long t1 = millis();

double xTrig = 285.0 - 37940.0 / (t1 - t0);

while (posConveyor < xTrig)

{

}

long t = millis();

posP2P(-18, 10, -165);

long t2 = millis();

//delay(4000);

//posCP(-21, 10, -167, -21, 10, -176);

posP2P(-18, 10, -176);

long t3 = millis();

gripper.on();

delay(200);

// choose where to place the item based on color

if (colorVal < blueLowerThreshold)

{

// color is red

posP2P(0, 0, -160);

posP2P(60, 0, -160);

}

else

{

// color is blue

posP2P(-20, 30, -160);

posP2P(-70, -20, -160);

}

gripper.off();

delay(300);

posP2P(0, 0, -140);

referencing();

}

}

步骤四 验证结果

最终我们出色的完成了我们的作品,在这里我们可以看到机器人可以成功的分拣物体了。