简介

步骤一 材料准备

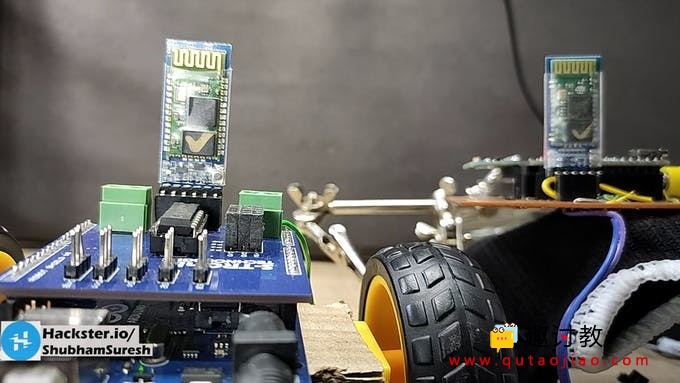

硬件准备:

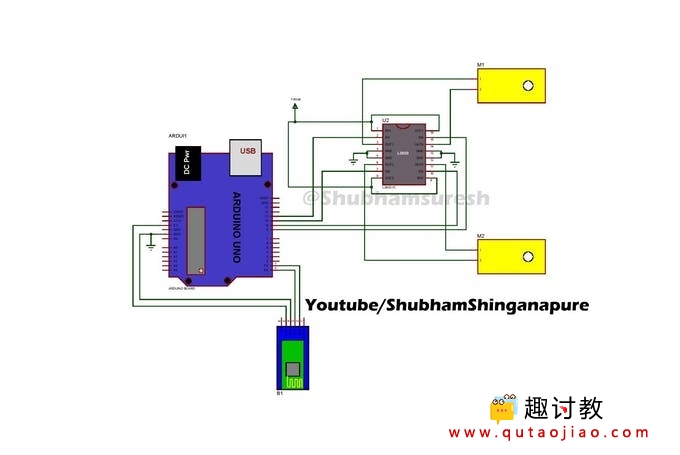

arduino uno

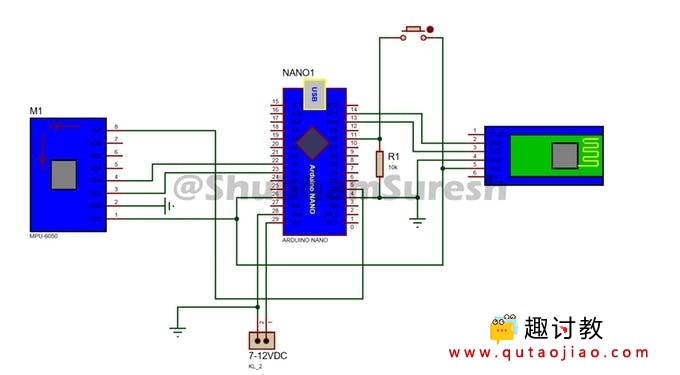

arduino nano R3

HC-05 蓝牙模块

MPU6050

DC motor 12V

轮子

L239D H桥电机驱动

9v 电池

软件准备:

arduino IDE

步骤二 原理说明

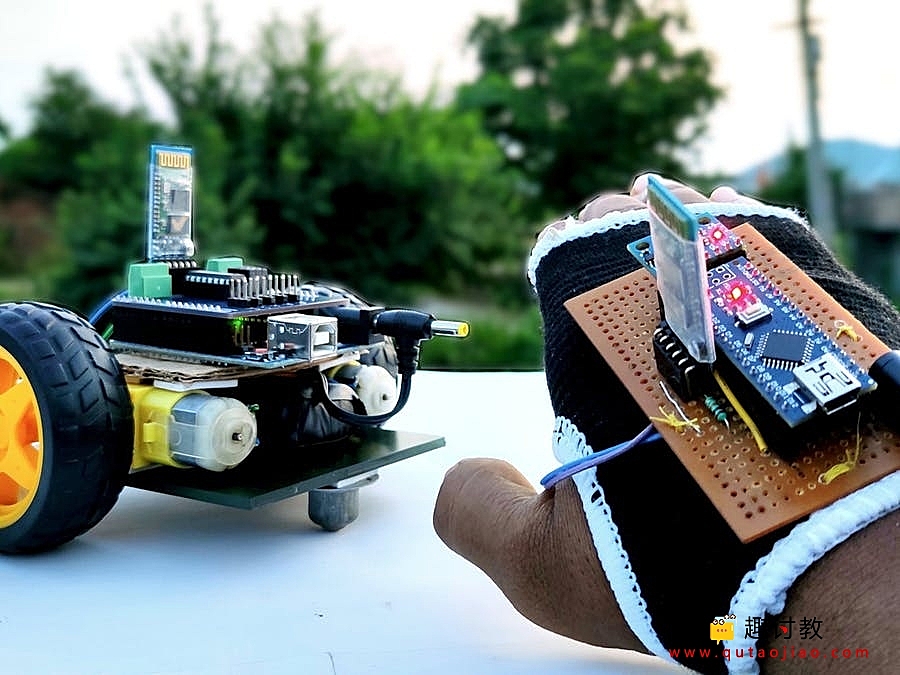

这是关于如何自己制作手势控制的车子。基本上,这是MPU-6050 3轴陀螺仪,加速度计的简单应用。您可以做更多的事情。通过了解如何使用它,如何将其与Arduino接口以及如何通过蓝牙模块传输其数据。在本文中,我将重点介绍两个HC-05蓝牙模块之间的蓝牙到蓝牙通信。

步骤三 电路搭建

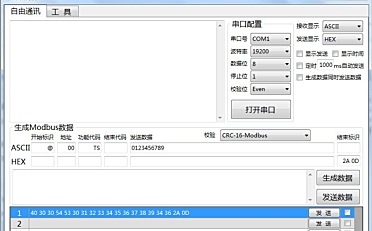

现在让我们谈谈蓝牙模块的配置。基本上,HC-05蓝牙模块带有从属模块出厂设置。这意味着我们可以通过插入数据将数据发送到jus模块。无需进行任何其他设置即可将数据从移动设备发送到HC-05模块。只需输入其默认密码(1234/0000)即可进行连接。但是,如果我们想使用此模块将数据发送到其他相同模块或移动设备,该怎么办?

在这个项目中,我们做同样的事情,通过蓝牙模块发送数据。由mpu-6050陀螺仪传感器收集到另一个蓝牙模块。

为此,首先我们需要配置这两个蓝牙模块。以便它们在开机后可以自动相互绑定。在这里,第一个模块充当从设备,它将接收来自远程单元的信号并将其安装在汽车上。并将第二个设备配置为主设备,该主设备将充当发送器单元并将数据发送到从设备,因此,首先将第一个蓝牙模块配置为从设备。为此,请按照此接线图将其与Arduino连接。

#include <SoftwareSerial.h>

SoftwareSerial BTSerial(10, 11); // RX | TX

void setup()

{

Serial.begin(9600);

Serial.println("Enter AT commands:");

BTSerial.begin(38400); // HC-05 default speed in AT command more

}

void loop()

{

// Keep reading from HC-05 and send to Arduino Serial Monitor

if (BTSerial.available())

Serial.write(BTSerial.read());

// Keep reading from Arduino Serial Monitor and send to HC-05

if (Serial.available())

BTSerial.write(Serial.read());

}

断开模块。按住模块上的ky,然后将其重新连接。您会看到led on模块的闪烁速度变慢。每2秒一次。这意味着HC-05处于AT命令模式。现在打开串行监视器,将波特率更改为9600,并将输出类型分别设置为NL和CR。现在在发送框中键入AT并将其发送。如果回答确定,则表示一切正常。但是,如果没有,并且出现一些错误,请再次发送AT。直到它回复正常或检查连接并再次发送AT…

从模块获得OK响应后,依次输入以下命令,

AT + ORGL并将其发送。此命令将模块设置为出厂设置。

AT + RMAAD此命令将从先前的任何配对中释放模块

AT + UART?检查模块的当前波特率

AT + UART = 38400,0,0设置波特率为38400

AT +角色?检查角色是从属角色还是主角色。它回答0或1。如果模块是从设备,则回答0,如果它是主设备,则它将回答1。

将角色设置为从设备。输入AT + ROLE = 0

AT + ADDR?检查模块地址。

记下该地址。按模块回答。获取此地址后,将完成从站模块的配置

现在该配置第二个蓝牙模块作为主设备了。将此模块与Arduino开发板连接,并使其进入AT模式。就像上一个一样。

按给定顺序输入这些AT命令。

AT + ORGL

AT + RMAAD

AT + UART?

AT + UART = 38400,0,0

AT +角色?

将此模块设置为主设备。AT +角色= 1

AT + CMODE = 0,因此模块将仅连接单个设备。默认设置为0

现在将此模块与从属设备绑定以执行此输入,

AT + BIND =“从站模块的地址”并全部完成

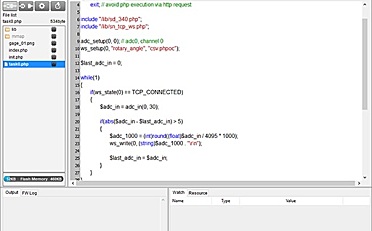

现在安装用于MPU-6050传感器I2C通讯的库。由于MPU-6050陀螺仪传感器具有I2C接口。从此处下载库和源代码:http : //www.mediafire.com/file/l8mru5emulb8x93/gesture_control_robot.rar/file

如果您已预先安装了这些库,请跳过此步骤。

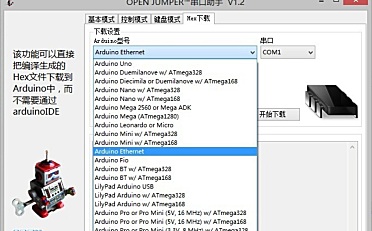

现在,使用USB电缆将汽车单元与PC连接。选择正确的串口和单板类型。并以名称“ Gesture_controled_Robot__car_unit_”上传程序。上载程序时,请确保电池和蓝牙模块未与汽车连接。

//program by Shubham Shinganapure on 3-10-2019

//

//for Gesture controled Robotic Car

int lm1=8; //left motor output 1

int lm2=9; //left motor output 2

int rm1=10; //right motor output 1

int rm2=11; //right motor output 2

char d=0;

void setup()

{

pinMode(lm1,OUTPUT);

pinMode(lm2,OUTPUT);

pinMode(rm1,OUTPUT);

pinMode(rm2,OUTPUT);

Serial.begin(38400);

sTOP();

}

void loop()

{

if(Serial.available()>0)

{

d=Serial.read();

if(d=='F')

{

ForWard();

}

if(d=='B')

{

BackWard();

}

if(d=='L')

{

Left();

}

if(d=='R')

{

Right();

}

if(d=='S')

{

sTOP();

}

}

}

void ForWard()

{

digitalWrite(lm1,HIGH);

digitalWrite(lm2,LOW);

digitalWrite(rm1,HIGH);

digitalWrite(rm2,LOW);

}

void BackWard()

{

digitalWrite(lm1,LOW);

digitalWrite(lm2,HIGH);

digitalWrite(rm1,LOW);

digitalWrite(rm2,HIGH);

}

void Left()

{

digitalWrite(lm1,LOW);

digitalWrite(lm2,HIGH);

digitalWrite(rm1,HIGH);

digitalWrite(rm2,LOW);

}

void Right()

{

digitalWrite(lm1,HIGH);

digitalWrite(lm2,LOW);

digitalWrite(rm1,LOW);

digitalWrite(rm2,HIGH);

}

void sTOP()

{

digitalWrite(lm1,LOW);

digitalWrite(lm2,LOW);

digitalWrite(rm1,LOW);

digitalWrite(rm2,LOW);

}

对远程单元执行相同的操作。通过远程名称打开程序。并将其上传到远程单元。

//program modified on 3/10/19 by // by Shubham Shinganapure.

//

//for Gesture controled Robotic Car (remote )

#include "I2Cdev.h"

#include "MPU6050_6Axis_MotionApps20.h"

//#include "MPU6050.h" // not necessary if using MotionApps include file

// Arduino Wire library is required if I2Cdev I2CDEV_ARDUINO_WIRE implementation

// is used in I2Cdev.h

#if I2CDEV_IMPLEMENTATION == I2CDEV_ARDUINO_WIRE

#include "Wire.h"

#endif

// class default I2C address is 0x68

// specific I2C addresses may be passed as a parameter here

// AD0 low = 0x68 (default for SparkFun breakout and InvenSense evaluation board)

// AD0 high = 0x69

MPU6050 mpu;

#define OUTPUT_READABLE_YAWPITCHROLL

// MPU control/status vars

bool dmpReady = false; // set true if DMP init was successful

uint8_t mpuIntStatus; // holds actual interrupt status byte from MPU

uint8_t devStatus; // return status after each device operation (0 = success, !0 = error)

uint16_t packetSize; // expected DMP packet size (default is 42 bytes)

uint16_t fifoCount; // count of all bytes currently in FIFO

uint8_t fifoBuffer[64]; // FIFO storage buffer

VectorFloat gravity;

Quaternion q;

float ypr[3]; // [yaw, pitch, roll] yaw/pitch/roll container and gravity vector

uint8_t teapotPacket[14] = { '$', 0x02, 0,0, 0,0, 0,0, 0,0, 0x00, 0x00, '\r', '\n' };

volatile bool mpuInterrupt = false; // indicates whether MPU interrupt pin has gone high

void dmpDataReady() {

mpuInterrupt = true;

}

#include <SoftwareSerial.h>

SoftwareSerial BTSerial(10, 11); // RX | TX

int bt=8;

int x =1;

void setup() {

#if I2CDEV_IMPLEMENTATION == I2CDEV_ARDUINO_WIRE

Wire.begin();

TWBR = 24; // 400kHz I2C clock (200kHz if CPU is 8MHz)

#elif I2CDEV_IMPLEMENTATION == I2CDEV_BUILTIN_FASTWIRE

Fastwire::setup(400, true);

#endif

// initialize serial communication

// (115200 chosen because it is required for Teapot Demo output, but it's

// really up to you depending on your project)

Serial.begin(115200);

BTSerial.begin(38400);

// while (!Serial); // wait for Leonardo enumeration, others continue immediately

Serial.println(F("Initializing I2C devices..."));

mpu.initialize();

// verify connection

Serial.println(F("Testing device connections..."));

Serial.println(mpu.testConnection() ? F("MPU6050 connection successful") : F("MPU6050 connection failed"));

// wait for ready

// load and configure the DMP

Serial.println(F("Initializing DMP..."));

devStatus = mpu.dmpInitialize();

// supply your own gyro offsets here, scaled for min sensitivity

mpu.setXGyroOffset(220);

mpu.setYGyroOffset(76);

mpu.setZGyroOffset(-85);

mpu.setZAccelOffset(1788);

// make sure it worked (returns 0 if so)

if (devStatus == 0) {

// turn on the DMP, now that it's ready

Serial.println(F("Enabling DMP..."));

mpu.setDMPEnabled(true);

// enable Arduino interrupt detection

Serial.println(F("Enabling interrupt detection (Arduino external interrupt 0)..."));

attachInterrupt(0, dmpDataReady, RISING);

mpuIntStatus = mpu.getIntStatus();

// set our DMP Ready flag so the main loop() function knows it's okay to use it

Serial.println(F("DMP ready! Waiting for first interrupt..."));

dmpReady = true;

// get expected DMP packet size for later comparison

packetSize = mpu.dmpGetFIFOPacketSize();

} else {

// ERROR!

// 1 = initial memory load failed

// 2 = DMP configuration updates failed

// (if it's going to break, usually the code will be 1)

Serial.print(F("DMP Initialization failed (code "));

Serial.print(devStatus);

Serial.println(F(")"));

}

// configure LED for output

pinMode(bt,INPUT);

}

// ================================================================

// === MAIN PROGRAM LOOP ===

// ================================================================

void loop() {

if(digitalRead(bt)==HIGH)

{

x++;

delay(150);

}

if((x%2)==0){

// if programming failed, don't try to do anything

if (!dmpReady) return;

// wait for MPU interrupt or extra packet(s) available

while (!mpuInterrupt && fifoCount < packetSize) {

// other program behavior stuff here

// .

// .

// .

// if you are really paranoid you can frequently test in between other

// stuff to see if mpuInterrupt is true, and if so, "break;" from the

// while() loop to immediately process the MPU data

// .

// .

// .

}

// reset interrupt flag and get INT_STATUS byte

mpuInterrupt = false;

mpuIntStatus = mpu.getIntStatus();

// get current FIFO count

fifoCount = mpu.getFIFOCount();

// check for overflow (this should never happen unless our code is too inefficient)

if ((mpuIntStatus & 0x10) || fifoCount == 1024) {

// reset so we can continue cleanly

mpu.resetFIFO();

Serial.println(F("FIFO overflow!"));

// otherwise, check for DMP data ready interrupt (this should happen frequently)

} else if (mpuIntStatus & 0x02) {

// wait for correct available data length, should be a VERY short wait

while (fifoCount < packetSize) fifoCount = mpu.getFIFOCount();

// read a packet from FIFO

mpu.getFIFOBytes(fifoBuffer, packetSize);

// track FIFO count here in case there is > 1 packet available

// (this lets us immediately read more without waiting for an interrupt)

fifoCount -= packetSize;

#ifdef OUTPUT_READABLE_YAWPITCHROLL

// display Euler angles in degrees

mpu.dmpGetQuaternion(&q, fifoBuffer);

mpu.dmpGetGravity(&gravity, &q);

mpu.dmpGetYawPitchRoll(ypr, &q, &gravity);

Serial.print("ypr\t");

Serial.print(ypr[0] * 180/M_PI);

Serial.print("\t");

Serial.print(ypr[1] * 180/M_PI);

Serial.print("\t");

Serial.println(ypr[2] * 180/M_PI);

if((ypr[1] * 180/M_PI)<= -25)

{BTSerial.write('F');

}

else if((ypr[1] * 180/M_PI)>= 25)

{BTSerial.write('B');

}

else if((ypr[2] * 180/M_PI)<= -25)

{BTSerial.write('L');

}

else if((ypr[2] * 180/M_PI)>= 20)

{BTSerial.write('R');

}

else{

BTSerial.write('S');

}

#endif

}

}

else{

BTSerial.write('S');

}

}

将从属蓝牙模块插入汽车单元,并在远程单元上主控蓝牙模块。一切都完成了。

让我们打开电源,即可开始……。

步骤四 编写程序

//program modified on 3/10/19 by // by Shubham Shinganapure.

//

//for Gesture controled Robotic Car (remote )

#include "I2Cdev.h"

#include "MPU6050_6Axis_MotionApps20.h"

//#include "MPU6050.h" // not necessary if using MotionApps include file

// Arduino Wire library is required if I2Cdev I2CDEV_ARDUINO_WIRE implementation

// is used in I2Cdev.h

#if I2CDEV_IMPLEMENTATION == I2CDEV_ARDUINO_WIRE

#include "Wire.h"

#endif

// class default I2C address is 0x68

// specific I2C addresses may be passed as a parameter here

// AD0 low = 0x68 (default for SparkFun breakout and InvenSense evaluation board)

// AD0 high = 0x69

MPU6050 mpu;

#define OUTPUT_READABLE_YAWPITCHROLL

// MPU control/status vars

bool dmpReady = false; // set true if DMP init was successful

uint8_t mpuIntStatus; // holds actual interrupt status byte from MPU

uint8_t devStatus; // return status after each device operation (0 = success, !0 = error)

uint16_t packetSize; // expected DMP packet size (default is 42 bytes)

uint16_t fifoCount; // count of all bytes currently in FIFO

uint8_t fifoBuffer[64]; // FIFO storage buffer

VectorFloat gravity;

Quaternion q;

float ypr[3]; // [yaw, pitch, roll] yaw/pitch/roll container and gravity vector

uint8_t teapotPacket[14] = { '$', 0x02, 0,0, 0,0, 0,0, 0,0, 0x00, 0x00, '\r', '\n' };

volatile bool mpuInterrupt = false; // indicates whether MPU interrupt pin has gone high

void dmpDataReady() {

mpuInterrupt = true;

}

#include <SoftwareSerial.h>

SoftwareSerial BTSerial(10, 11); // RX | TX

int bt=8;

int x =1;

void setup() {

#if I2CDEV_IMPLEMENTATION == I2CDEV_ARDUINO_WIRE

Wire.begin();

TWBR = 24; // 400kHz I2C clock (200kHz if CPU is 8MHz)

#elif I2CDEV_IMPLEMENTATION == I2CDEV_BUILTIN_FASTWIRE

Fastwire::setup(400, true);

#endif

// initialize serial communication

// (115200 chosen because it is required for Teapot Demo output, but it's

// really up to you depending on your project)

Serial.begin(115200);

BTSerial.begin(38400);

// while (!Serial); // wait for Leonardo enumeration, others continue immediately

Serial.println(F("Initializing I2C devices..."));

mpu.initialize();

// verify connection

Serial.println(F("Testing device connections..."));

Serial.println(mpu.testConnection() ? F("MPU6050 connection successful") : F("MPU6050 connection failed"));

// wait for ready

// load and configure the DMP

Serial.println(F("Initializing DMP..."));

devStatus = mpu.dmpInitialize();

// supply your own gyro offsets here, scaled for min sensitivity

mpu.setXGyroOffset(220);

mpu.setYGyroOffset(76);

mpu.setZGyroOffset(-85);

mpu.setZAccelOffset(1788);

// make sure it worked (returns 0 if so)

if (devStatus == 0) {

// turn on the DMP, now that it's ready

Serial.println(F("Enabling DMP..."));

mpu.setDMPEnabled(true);

// enable Arduino interrupt detection

Serial.println(F("Enabling interrupt detection (Arduino external interrupt 0)..."));

attachInterrupt(0, dmpDataReady, RISING);

mpuIntStatus = mpu.getIntStatus();

// set our DMP Ready flag so the main loop() function knows it's okay to use it

Serial.println(F("DMP ready! Waiting for first interrupt..."));

dmpReady = true;

// get expected DMP packet size for later comparison

packetSize = mpu.dmpGetFIFOPacketSize();

} else {

// ERROR!

// 1 = initial memory load failed

// 2 = DMP configuration updates failed

// (if it's going to break, usually the code will be 1)

Serial.print(F("DMP Initialization failed (code "));

Serial.print(devStatus);

Serial.println(F(")"));

}

// configure LED for output

pinMode(bt,INPUT);

}

// ================================================================

// === MAIN PROGRAM LOOP ===

// ================================================================

void loop() {

if(digitalRead(bt)==HIGH)

{

x++;

delay(150);

}

if((x%2)==0){

// if programming failed, don't try to do anything

if (!dmpReady) return;

// wait for MPU interrupt or extra packet(s) available

while (!mpuInterrupt && fifoCount < packetSize) {

// other program behavior stuff here

// .

// .

// .

// if you are really paranoid you can frequently test in between other

// stuff to see if mpuInterrupt is true, and if so, "break;" from the

// while() loop to immediately process the MPU data

// .

// .

// .

}

// reset interrupt flag and get INT_STATUS byte

mpuInterrupt = false;

mpuIntStatus = mpu.getIntStatus();

// get current FIFO count

fifoCount = mpu.getFIFOCount();

// check for overflow (this should never happen unless our code is too inefficient)

if ((mpuIntStatus & 0x10) || fifoCount == 1024) {

// reset so we can continue cleanly

mpu.resetFIFO();

Serial.println(F("FIFO overflow!"));

// otherwise, check for DMP data ready interrupt (this should happen frequently)

} else if (mpuIntStatus & 0x02) {

// wait for correct available data length, should be a VERY short wait

while (fifoCount < packetSize) fifoCount = mpu.getFIFOCount();

// read a packet from FIFO

mpu.getFIFOBytes(fifoBuffer, packetSize);

// track FIFO count here in case there is > 1 packet available

// (this lets us immediately read more without waiting for an interrupt)

fifoCount -= packetSize;

#ifdef OUTPUT_READABLE_YAWPITCHROLL

// display Euler angles in degrees

mpu.dmpGetQuaternion(&q, fifoBuffer);

mpu.dmpGetGravity(&gravity, &q);

mpu.dmpGetYawPitchRoll(ypr, &q, &gravity);

Serial.print("ypr\t");

Serial.print(ypr[0] * 180/M_PI);

Serial.print("\t");

Serial.print(ypr[1] * 180/M_PI);

Serial.print("\t");

Serial.println(ypr[2] * 180/M_PI);

if((ypr[1] * 180/M_PI)<= -25)

{BTSerial.write('F');

}

else if((ypr[1] * 180/M_PI)>= 25)

{BTSerial.write('B');

}

else if((ypr[2] * 180/M_PI)<= -25)

{BTSerial.write('L');

}

else if((ypr[2] * 180/M_PI)>= 20)

{BTSerial.write('R');

}

else{

BTSerial.write('S');

}

#endif

}

}

else{

BTSerial.write('S');

}

}

步骤五 验证结果

接下来我们就可以看到小车可以跟随手势进行移动了。